Join Our Mailiing List

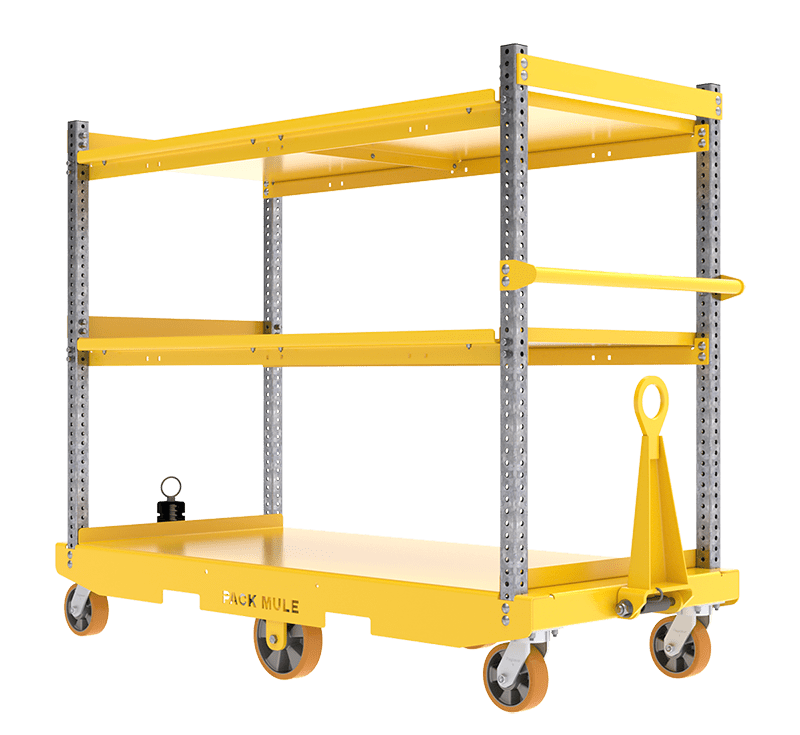

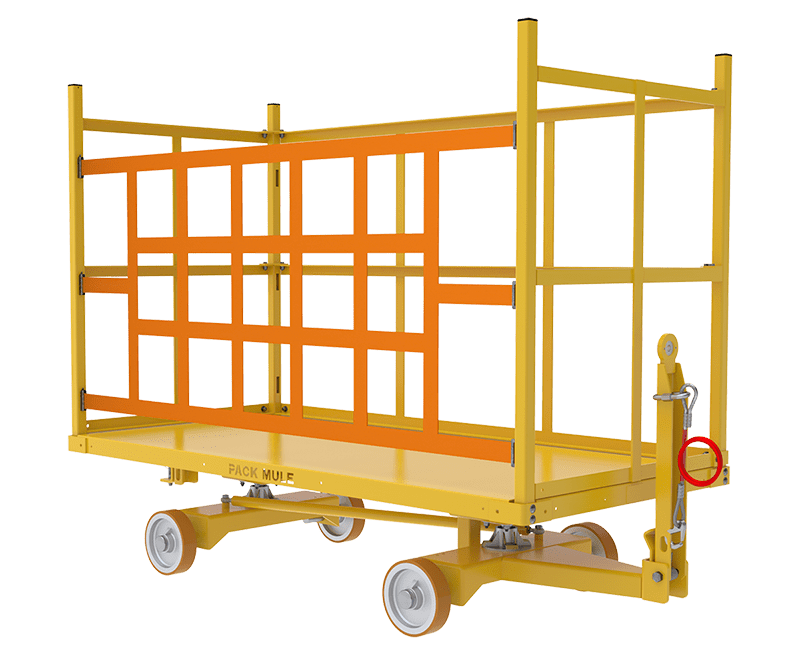

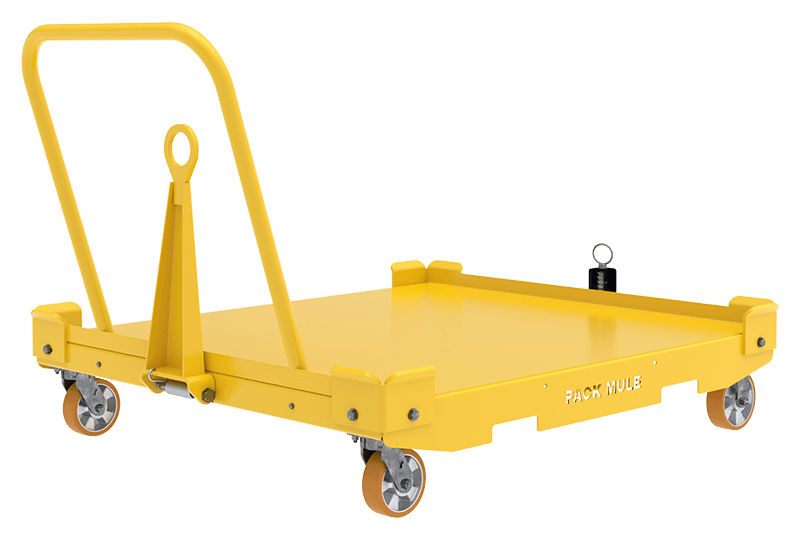

Try a PACK MULE vehicle and trailer in your facility.

We've been helping manufacturers and distributors move materials horizontally for more than 60 years, and we've learned what customers need to get the job done. That's the reason we build PACK MULE to a higher standard and why we encourage you to test them in your facility, doing your work.