Our customers count on Pack Mule towable trailers to get the job done. That's the reason we build them like we do.

The PACK MULE Difference

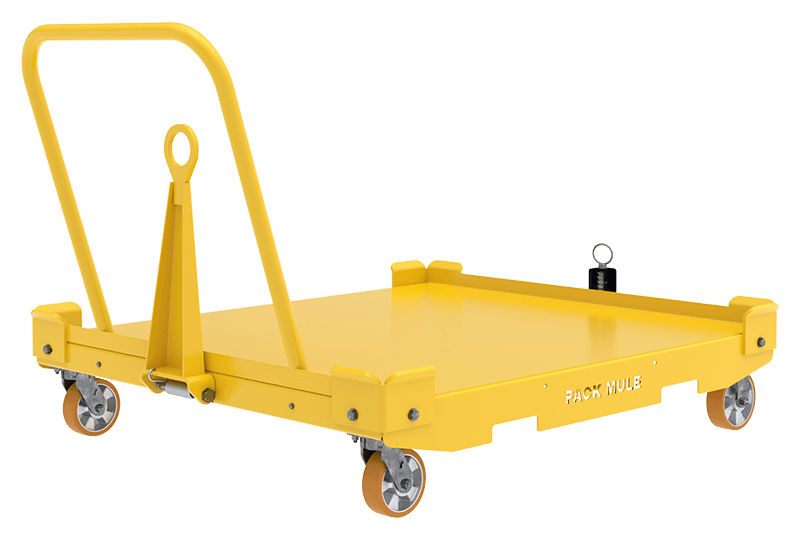

- RUGGED CONSTRUCTION: Deck formed from a single sheet of heavy-duty steel. Others use lighter-weight steel and welded decks.

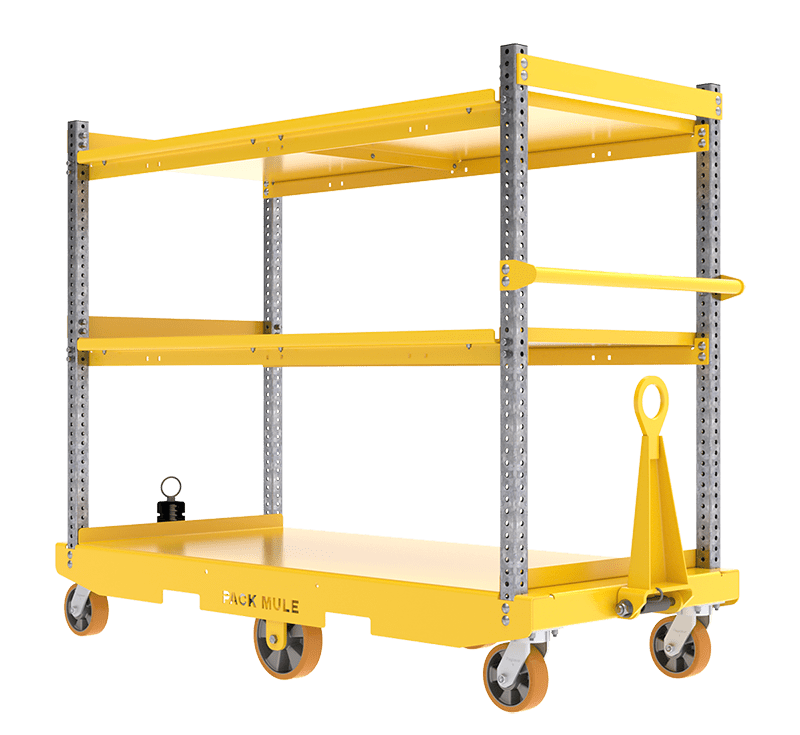

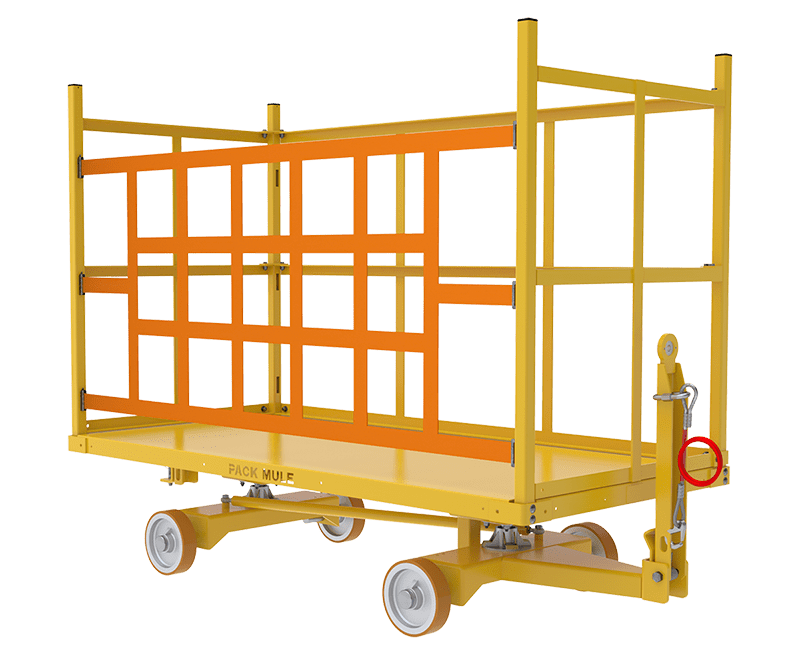

- FLEXIBLE CONFIGURATION: Get the trailer you need fully configured without delays and order accessories at any time if your needs change.

- SERVICE AND SPEED: We've learned what it takes to buy a trailer from the others. We'll get you the trailer you need with less hassle and in half the time as the others. Sometimes sooner.

- THREE YEAR WARRANTY: Pack Mule offers the best warranty in the business, just like we do on our electric vehicles.

From highly maneuverable carts and order pickers to precision tracking trains of configurable trailers. PACK MULE has hundreds of equipment configurations to meet your application needs.

DON'T TAKE OUR WORD FOR IT.

Try a PACK MULE vehicle and trailer in your facility.

No commitment required.

We've been helping manufacturers and distributors move materials horizontally for more than 60 years, and we've learned what customers need to get the job done. That's the reason we build PACK MULE to a higher standard and why we encourage you to test them in your facility, doing your work.